Pallet Live Racking Systems

Pallet live racking systems are ideal for operations that require frequent product rotation and have limited space. This system offers high storage density without the need for block stacking your pallets. Most pallet live systems operate on a first-in, first-out (FIFO) basis, ensuring automatic stock rotation. However, push back systems use a last-in, first-out (LIFO) principle.

How It Works

Also known as dynamic storage or gravity flow racking, this system consists of inclined roller tracks and operates with two access faces. Pallets are loaded into dedicated lanes of inclined gravity rollers set at fixed gradients. When you remove a pallet, gravity and an automatic braking system move the pallets behind it to the pick face at a controlled pace.

Applications

Pallet live racking is perfect for storing perishable goods and any fast-moving items that need to be retrieved quickly. This compact storage system maximizes capacity and saves time in pallet handling.

Integration in Complex Systems

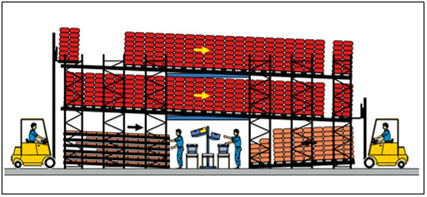

Pallet live storage often integrates into more complex order-picking systems. For instance, a FIFO principle live storage pallet buffer on top, with loading and unloading aisles used for restocking and relocating goods from the buffer stock into feeder lanes, leads to the picking tunnel where individual orders can be picked and collated by hand.

Benefits of Pallet Live Racking

Pallet live racking enables you to:

- Automatically rotate stock

- Increase throughput speed

- Achieve high-density storage

- Maximize your floor space

- Reduce damage

- Provide excellent stock control

Key Advantages

Pallet live racking ensures perfect product turnover with no interference between storage and extraction of pallets. It can be accessed using most types of forklift trucks.

Contact Us

To book your free site survey and design consultation, call our team today at 01937 585057.