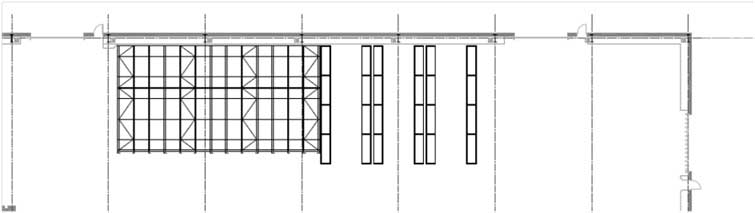

Drive In and APR Pallet Racking Installation for a Packaging Manufacturer in Hartlepool, County Durham

Project requirements: Design, technical and structural loadings delivery, installation, and consulting with fire protection contractors.

Project investment: £60K

Project detail: 2h Storage Solutions designed supplied and installed a mixture of drive in and APR pallet racking for 1000plus pallet positions to a height of over 11mtrs.

[wpw_ba_viewer width=”650″ height=”650″ anim_speed=”600″ start_percent=”0.5″ disable_intro=”false”]

[wpw_ba_img src=”https://palletracking-uk.co.uk/wp-content/uploads/2015/10/Case-study-packaging-manufacture-harlepool-before-pallet-racking-installation-image.jpg” alt=”before pallet racking installation” data_second=”https://palletracking-uk.co.uk/wp-content/uploads/2015/10/Case-study-packaging-manufacture-hartlepool-after-pallet-racking-installation-image.jpg” alt=”after racking installation “title=”Pallet racking installation at Hartlepool manufacturer warehouse” data_info=”Pallet racking installation at Hartlepool manufacturer warehouse”]

[/wpw_ba_viewer]

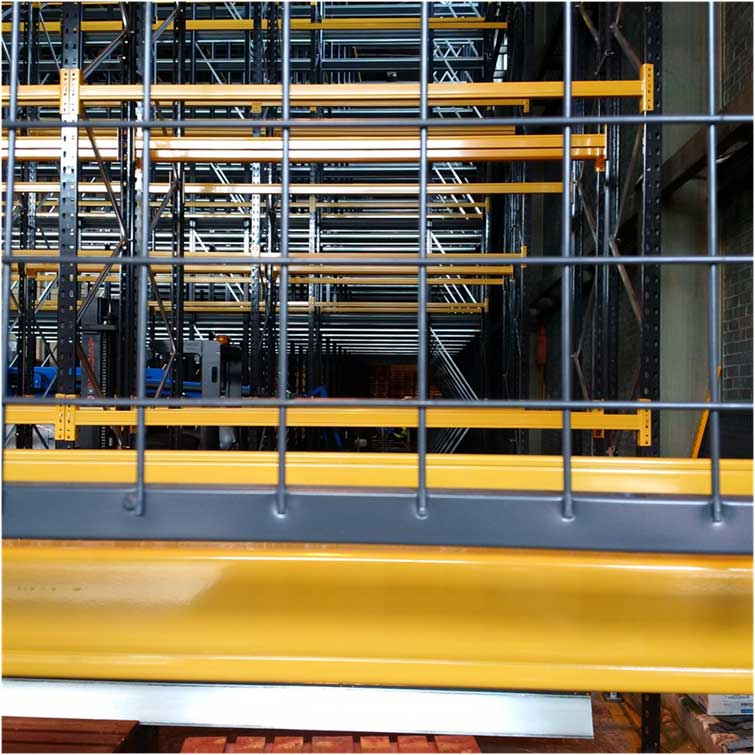

2h Storage Solutions won this contract against stiff competition on price and specification using a mixture of Polypal and Link 51 systems all supplied direct from UK factories by the Moresecure group. With the capacity for over 1000 pallet positions in racking reacting a height just a few hundred mm below the underside of the roof. With the system extending to a height of 11,154mm working with the latest fork lift trucks featuring on mast camera systems.

| Capacity APR (subject to onsite survey):Capacity Drive in:Total Capacity: | 288 (based on 1000mm x 1200mm pallets)819 (1200 x 1000mm) or 546 (1200mm x 1500mm1107(1200 x 1000mm) or larger pallets in drive in 834 |

| Maximum Beam Loading UDL per pair: | 1000kgs |

| Maximum Bay loading: | 5000kgs |

We liaised with both the fire Protection Company who installed the sprinkler system and FM Global who advised of the customer’s insurance company’s specification and criteria.

The system was installed using a variety of plant FLT and specialist scissor lifts to reach heights involved in this installation. We started the project on site with a team of seven of our highly skilled storage equipment installers using specialist lifting equipment to lift the frames and components to over 11mtrs high. The racking was fitted with the latest in racking protection using a mixture of steel amco style end barriers and ballistic grade polymer upright protectors.