Multi-tier mezzanine floor automated packaging system for multi-site shoe retailer Yorkshire

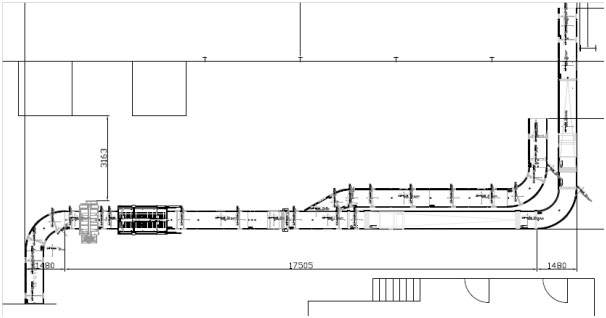

Project requirements: Functional design specification, mechanical, electrical, controls and control programming, installation and commissioning of fully automated and computer logic controlled conveyor and packing system.

Project investment: CIRCA £100K

Project detail: 2h Storage Solutions carried out the complete design, build, installation and commissioning of fully automated picking and dispatch system.

Professional Partners: Interroll conveyors, Opensoft Systems Ltd controls, automation logic and electrical design works, Minster Plumbing & Heating Ltd electrical installations and onsite design works.

Design installation and commissioning of a fully automated multi-tier mezzanine floor picking and dispatch system to include multiple runs of gravity, powered belt, powered roller conveyors auto case sealer taper machine and automated plastic banding machine.

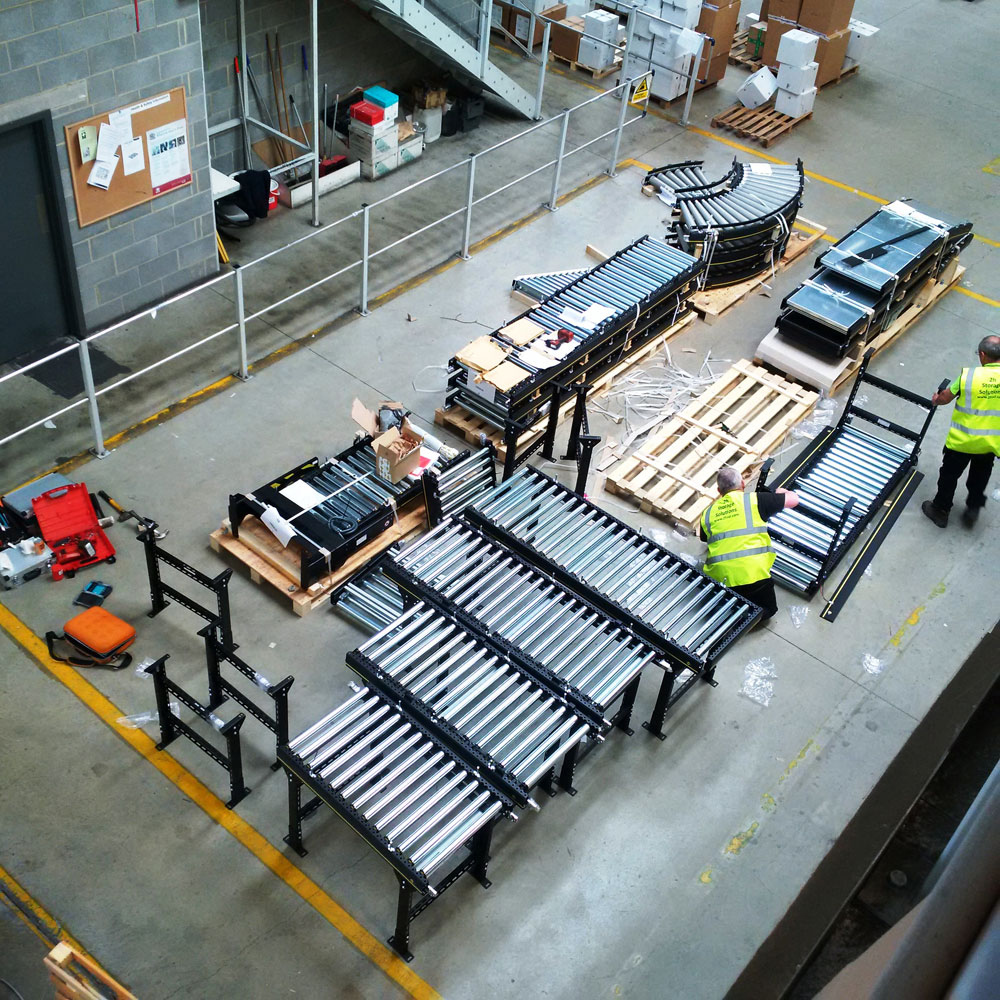

Equipment arrives on site:

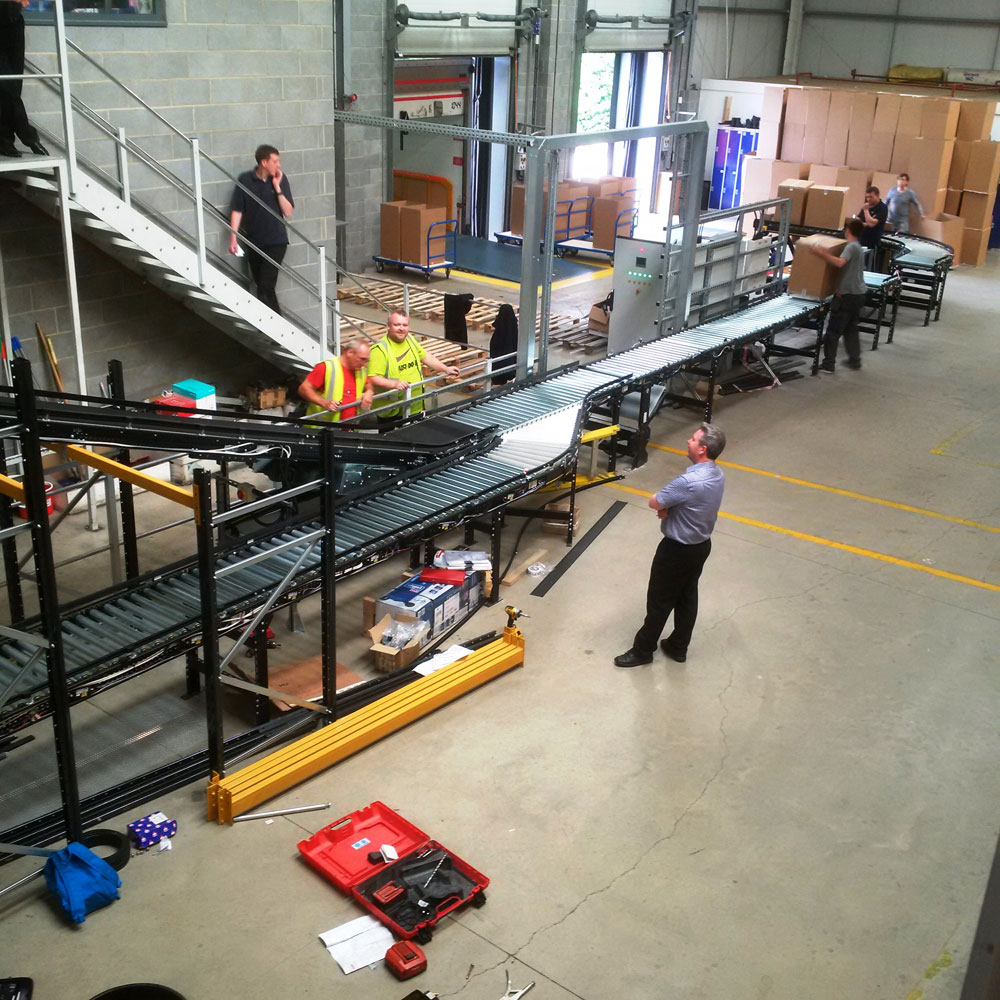

Installation begins

Automation and electrical installation begins.

The team from Opensoft and Minster Electrical discussing the optimum system design and functionality.

Mechanical installation team, electrical installation team and customer watch the first test boxes make their maiden voyage on the conveyor.

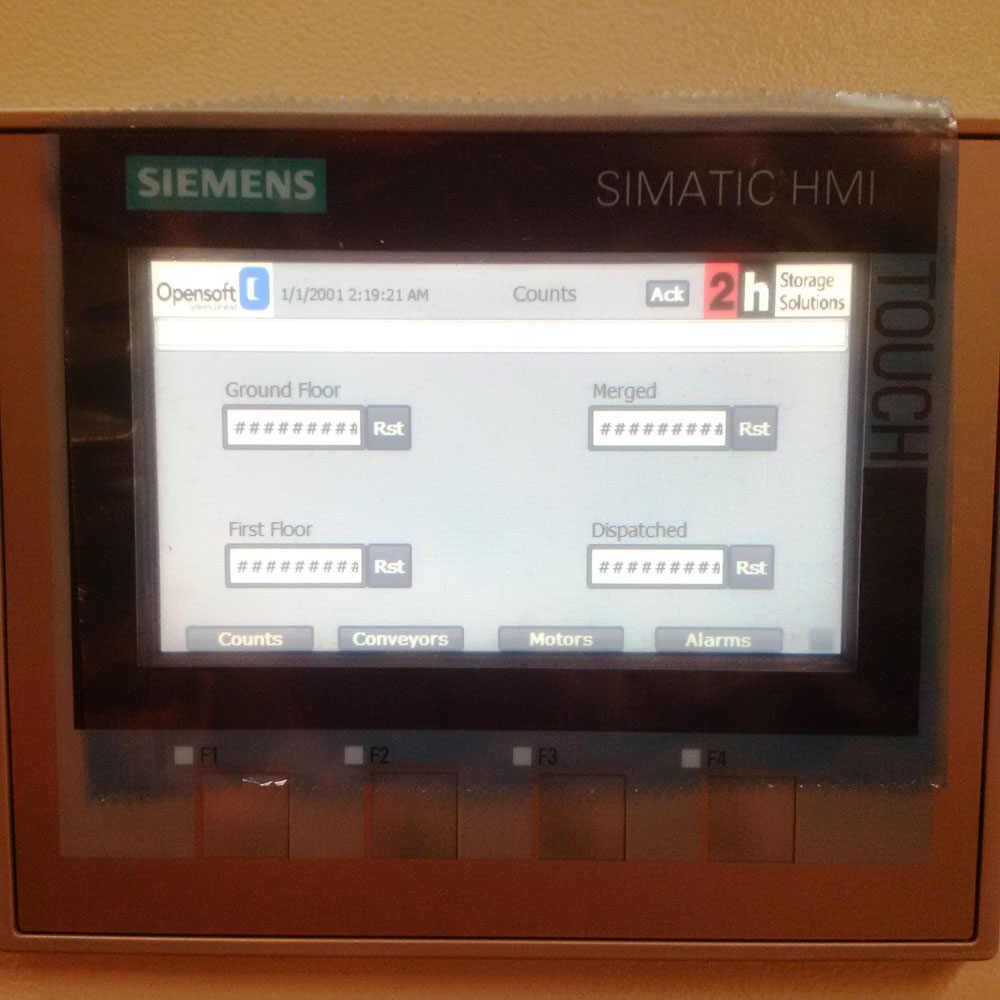

The team from Opensoft complete the I O testing of the electrical installation.

Logic is loaded onto Programmable logic controller and Human Machine Interface.

First boxes go through the auto case sealer (taping machine)

Control cabinet and end of line work station.